The Case for Replacing Microplastics at the Source Has Never Been Clearer

Another major report on microplastics just landed in California, and it underscores exactly why RWDC exists. The products people use every day are shedding microscopic plastic particles into the air we breathe and the food we eat. The solution isn’t more filters, warnings, or end-of-life fixes.

It’s better materials, designed from the start to protect human health.

Another Day, Another Disturbing Report

California’s Department of Toxic Substances Control (DTSC) released its latest overview of microplastics in consumer products, and the findings confirm what researchers, health advocates, and early movers like RWDC have been emphasizing for years: exposure isn’t occasional, incidental, or tied to a single product category. It’s structural. It’s routine. And it’s happening inside homes, schools, restaurants, and workplaces every day.

The report tracks how familiar items shed microplastics through ordinary use. Baby bottles made from polypropylene release particles when heated or shaken during formula preparation. Plastics used in food packaging — from beverage bottles and caps to cling films, snack wrappers, and polystyrene takeout containers — shed microplastics under heat, friction, and simple mechanical stress. Children’s toys, especially slimes, foams, polymer clays, and glitter-based products, transfer primary microplastics to hands, surfaces, and mouths.

Even products most people never consider contribute to this ongoing cycle. Water-based interior paints release microplastics when brushes and rollers are washed out, and dried paint layers shed particles into indoor dust over time. Detergents and fabric softeners rely on polymers and fragrance microcapsules that persist through wastewater treatment and travel into waterways. Agricultural plastic film mulch breaks down directly into soil, affecting everything from microbial communities to crop health.

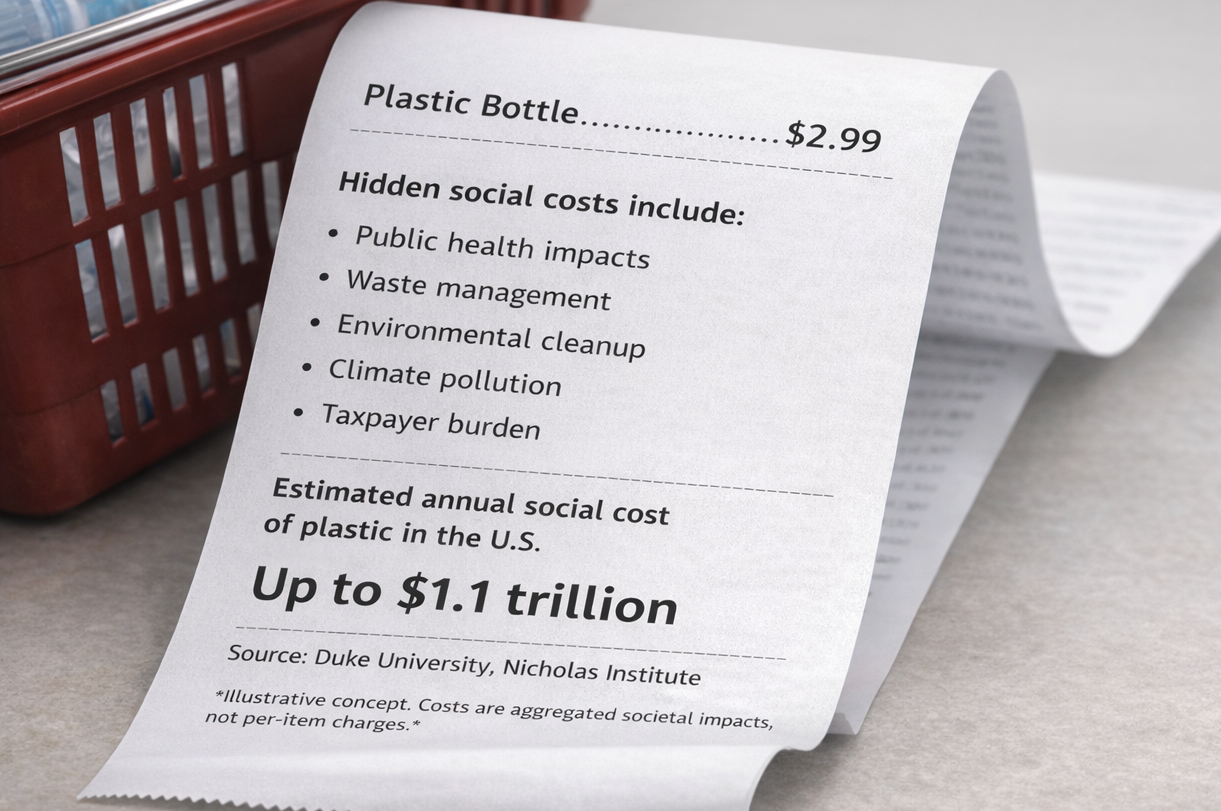

When these pathways converge, the picture becomes impossible to dismiss: microplastics flow into our environment, and our bodies, because the materials at the foundation of consumer products were never designed with human health in mind. They were designed for convenience, cost, and scale.

RWDC: Built to Change the Game

The encouraging element in DTSC’s findings is its acknowledgment that alternatives already exist. Glass, stainless steel, cellulose, mineral-based materials, paper systems, and genuinely biodegradable biopolymers, including PHA, offer realistic, high-performance options that do not leave behind persistent particles. These are not hypothetical materials. They are commercially viable today.

What’s needed now is commitment — from regulators, manufacturers, and brands who understand that the era of microplastic-dependent product design is ending.

California’s report will influence which products are designated as “Priority Products,” triggering reformulation requirements and accelerating the shift to safer materials. Globally, the movement is already gaining traction, with the European Union phasing out several categories of intentionally added microplastics by 2029.

Time for Action

The momentum is real. The science is clear. And the opportunity is enormous.

Microplastic exposure may be a daily reality, but it doesn’t have to be our future. RWDC is leading the shift toward materials that protect human health and return safely to the earth. It’s the only path forward where the products we rely on add value to our lives without leaving a permanent trace.